Sidewall conveyor belts

Possible to convey at steep angle with big capacity in a limited space

Available in all Sinoconve cover rubber qualities including abrasion resistant,heat resistant,fire resistant,cold resistant and oil resistant

Reinforcement inside sidewall perfectly combine flexibility and strength to effectively avoid torn

Special rubber compounds provide cleats superior resistant to impact,rip and tear

Twice hot vulcanizing give outstanding flexibility,high strength and durability to Sinoconve sidewall conveyor belts

The entire sidewall conveyor belts are highly duable,low elongation and long lasting

- Specification

- Manufacturing

- Certificates

| Based belt width(B) | Sidewall height(H) | Cleat height(H1) | Bottom width of sidewall(B1) | Cleat width(B2) | Empty width(B3) |

| 300 | 40 | 35 | 25 | 180 | 35 |

| 60 | 55 | 50 | 120 | 40 | |

| 80 | 75 | ||||

| 400 | 60 | 55 | 50 | 180 | 60 |

| 80 | 75 | ||||

| 100 | 90 | ||||

| 500 | 80 | 75 | 50 | 250 | 75 |

| 100 | 90 | ||||

| 120 | 110 | ||||

| 650 | 100 | 90 | 50 | 350 | 100 |

| 120 | 110 | ||||

| 160 | 140 | 75 | 300 | ||

| 800 | 120 | 110 | 50 | 460 | 120 |

| 160 | 140 | 75 | 410 | ||

| 200 | 180 | ||||

| 1000 | 160 | 140 | 75 | 550 | 150 |

| 200 | 180 | ||||

| 240 | 220 | ||||

| 1200 | 160 | 140 | 75 | 690 | 180 |

| 200 | 180 | ||||

| 240 | 220 | ||||

| 300 | 260 | 100 | 640 | ||

| 1400 | 200 | 180 | 75 | 830 | 210 |

| 240 | 220 | ||||

| 300 | 260 | 100 | 780 | ||

| 400 | 360 |

| Cleat type | Cleat height(mm) | Bottom width(mm) | Weight(kg/m) | Min. drum dia.(mm) | Production length(m) |

| t | 20 | 40 | 0.28 | 75 | 3/5 |

| 25 | 40 | 0.3 | 75 | 3/5 | |

| 35 | 55 | 0.55 | 100 | 3/5 | |

| 40 | 70 | 0.6 | 125 | 3/5 | |

| 55 | 80 | 1.45 | 125 | 3/5 | |

| 75 | 80 | 1.8 | 150 | 3/5 | |

| 90 | 110 | 2.5 | 250 | 3/5 | |

| 110 | 110 | 2.8 | 315 | 3/5 | |

| 140 | 160 | 6.6 | 400 | 2.5 | |

| 180 | 160 | 8.3 | 500 | 2.5 | |

| 230 | 175 | 10.46 | 630 | 2.5 | |

| ts | 110 | 160 | 7.9 | 315 | 3 |

| 140 | 160 | 9.25 | 400 | 3 | |

| 180 | 160 | 11.5 | 500 | 3 | |

| 230 | 160 | 13.5 | 630 | 3 | |

| 250 | 160 | 14.6 | 630 | 3 | |

| 280 | 160 | 17.65 | 800 | 3 | |

| 360 | 160 | 19.25 | 1000 | 3 | |

| tc | 75 | 80 | 1.8 | 150 | 3/5 |

| 90 | 110 | 2.5 | 250 | 3/5 | |

| 110 | 110 | 2.8 | 315 | 3/5 | |

| 140 | 160 | 6.6 | 400 | 2.5 | |

| 180 | 160 | 8.3 | 500 | 2.5 | |

| 230 | 175 | 10.46 | 630 | 2.5 | |

| tcs | 110 | 160 | 7.9 | 315 | 3 |

| 140 | 160 | 9.25 | 400 | 3 | |

| 180 | 160 | 11.5 | 500 | 3 | |

| 230 | 160 | 13.5 | 630 | 3 | |

| 250 | 160 | 14.6 | 630 | 3 | |

| 280 | 160 | 17.65 | 800 | 3 | |

| 360 | 160 | 19.25 | 1000 | 3 |

(Type “T” and “TS” are most suitable to convey materials in an angle bellow 40 degree whereas type “TC” and “TCS” are appliable in an angle above 40 degree)

(Type “TS” and “TCS” are inlaid design,highly suitable for quick maintenance of wear and tear.)

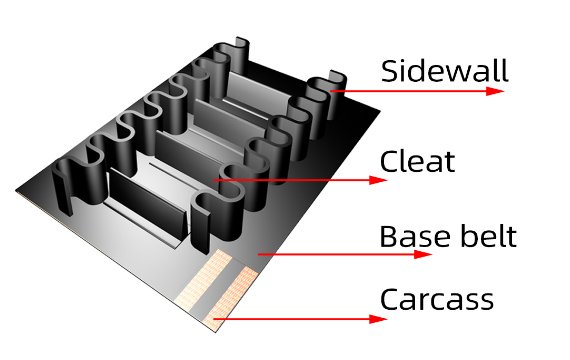

Sidewall conveyor belts structure

Sidewall conveyor belts are composed of three parts:base belt,sidewall and cleats.Sidewall effectively protect bulk materials from sideslip and scatter.

It is designed by most experienced engineers to corrugate shape and can withstand highly stress and repeated flexing

Cleats are the main part to carry materials in a high capacity and steep angle,which is T or TC type usually.

These two parts are connected with base belt by second hot vulcanizing,which creat a super-strength bond between sidewall,cleats and base belt.

Tensile strength test of sidewall conveyor belt

Sinoconve conveyor belt will be tested for tensile strength, abrasion resistance and adhesion before leaving the factory to determine whether the conveyor belt meets customer requirements.

Conveyor belt shipping and packaging

Sinoconve will provide packaging advice based on the type of conveyor belt you ordered.Sinoconve conveyor belt provides three packaging methods: round roll,glasses roll & oval roll.

Conveyor belt outsourcing pp tarpaulin, color can be customized, and also provide pallet (wood/metal) and iron frame options.

Quality control

What is a sidewall conveyor belt

Sidewall conveyor belt is composed of three parts: base belt, sidewall and diaphragm. The rib plays a role in preventing the material from slipping and falling. In order to facilitate bypassing the drum, the ribs are designed to be corrugated; the function of the diaphragm is to support the material, in order to achieve large inclination conveying, the T-type TC type is used. The ribs and the diaphragm are connected with the base tape by the method of secondary vulcanization, which has a high connection strength.

|

Cleat Height | 1″ | 1.5″ | 2″ | 2.5″ | 3″ | 3.5″ | 4″ | 5″ | 6″ |

| Min. Pulley Dia. (D1) | 4″ | 5″ | 6″ | 8″ | 10″ | 14″ | 14″ | 18″ | 18″ |

|

Cleat Height | 2″ | 2.5″ | 3″ | 3.5″ | 4″ | 4.5″ | |||

| Min. Pulley Dia. (D1) | 6″ | 8″ | 8″ | 10″ | 14″ | 14″ |

|

Cleat Height | 3″ | 3.5″ | 4″ | 4.5″ | 5″ | 5.5″ | 7″ | 9″ | |

| Min. Pulley Dia. (D1) | 8″ | 11″ | 12″ | 12″ | 16″ | 16″ | 16″ | 18″ |

|

Cleat Height | 4.5″ | 5″ | 5.5″ | 6″ | 7″ | 9″ | |||

| Min. Pulley Dia. (D1) | 14″ | 14″ | 14″ | 14″ | 14″ | 14″ |