Flame resistant conveyor belt

Sinoconve heat resistant conveyor belts are specially designed to handle materials which surface temperature is between 100℃ to 300℃,like sinter,clinker,casting sand,hot coke.etc.

The belt is reinforced by multi plies EP/Nylon fabric,and covered by heat resistant rubber which is mixed by special designed formula and process

As the working surface,top cover rubber contact with hot materials directly.General purpose conveyor belts will easily crack and hardening on this condition.

Sinoconve have 4 kinds of cover rubber formula to protect the whole belt from high temperature,crack and hardening caused by heat,abrasion and ageing.

EPDM is widely proved to be an excellent material to enhance the heat-resistant property of the cover rubber of the belt.

- Specification

- Manufacturing

- Certificates

| Item | Classes | |||||||

| T1 | T2 | T3 | T4 | |||||

| Test temperature | ||||||||

| ≤100℃ | ≤125℃ | ≤150℃ | ≤175℃ | |||||

| Change range allow | ||||||||

| Hardness | The difference between the before and after aging | 20 | 20 | ±20 | ±20 | |||

| Maximum value after aging | 85 | 85 | 85 | 85 | ||||

| Tensile strength | Performance change rate | -25 | -30 | -40 | -40 | |||

| Minimum value after aging | 12 | 10 | 5 | 5 | ||||

| Elongation | Change rage after aging | -50 | -50 | -55 | -55 | |||

| Minimum value after aging | 200 | 200 | 180 | 180 | ||||

| Adhesive | Top cover rubber to ply | Average value | 2.1 | |||||

| Minimum value | 1.7 | |||||||

| Ply to ply | Average value | 2.1 | ||||||

| Minimum value | 1.7 | |||||||

| Ply to Bottom cover rubber | Average value | 2.1 | ||||||

| Minimum value | 1.7 | |||||||

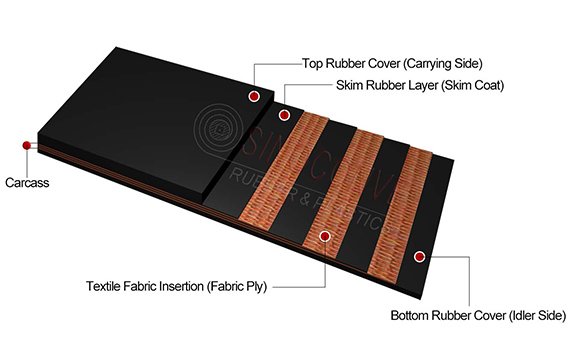

Heat resistant conveyor belts structure

EP rubber conveyor belt consists of top rubber cover, carcass and bottom rubber cover.

Conveyor belt carcass consists of fabric and skim rubber,provide EP100, EP125, EP150, EP200, EP250 and other strength conveyor belt fabrics,Carcass thickness and fabric layers are customized according to conveyor belt requirements.z

Heat resistant conveyor belt testing procedure

Sinoconve conveyor belt will be tested for tensile strength, abrasion resistance and adhesion before leaving the factory to determine whether the conveyor belt meets customer requirements.

Conveyor belt shipping and packaging

Sinoconve will provide packaging advice based on the type of conveyor belt you ordered.Sinoconve conveyor belt provides three packaging methods: round roll,glasses roll & oval roll.

Conveyor belt outsourcing pp tarpaulin, color can be customized, and also provide pallet (wood/metal) and iron frame options.

Quality control

What is Heat resistant conveyor belt

Heat resistant conveyor belt is made of multi-layer rubber polyester cloth covered with high-temperature or heat-resistant rubber and bonded together by high-temperature vulcanization. It is suitable for conveying hot coke, cement, slag and hot castings below 240 °C. Heat-resistant conveyor belts can be divided into four types:

- Type I(T1): It can withstand the test temperature of not more than 100 °C, and the maximum short-term operating temperature is 150 °C.

- Type II(T2): can withstand the test temperature not greater than 125 ℃, the maximum short-term operating temperature is 170 ℃.

- Type III(T3): can withstand the test temperature of not more than 150 ℃, the maximum short-term operating temperature is 200 ℃.

- Type IV(T4): can withstand the test temperature of not more than 175 ℃, the maximum short-term operating temperature is 400 ℃.